Enhancing Assets Management with Dashboard & Design System Integration

Background

The Asset platform helps organizations track assets, streamline operations, and ensure compliance. However, improvements were needed to enhance visibility, reduce friction, and drive greater operational efficiency.

Overview

Adding a global dashboard and integrating the Evo Design System improved user experience by enhancing visibility, simplifying workflows, and strengthening compliance. This case study covers the challenges, solutions, and impact.

Assets Management

Problem

Addressing Critical Issues in Asset Oversight

Fragmented Asset Visibility

Without a unified view, managing assets across multiple facilities was inefficient and fragmented, causing delays and making it harder to make informed, timely decisions.

Inconsistent User Experience

The lack of a standardized design system caused inconsistent UI components and a disjointed interface across modules.

Limited Functionality

Users needed advanced features like improved tracking, maintenance capabilities, and comprehensive reporting tools to support complex operations and ensure compliance.

Solution

Enhancing Visibility and Consistency

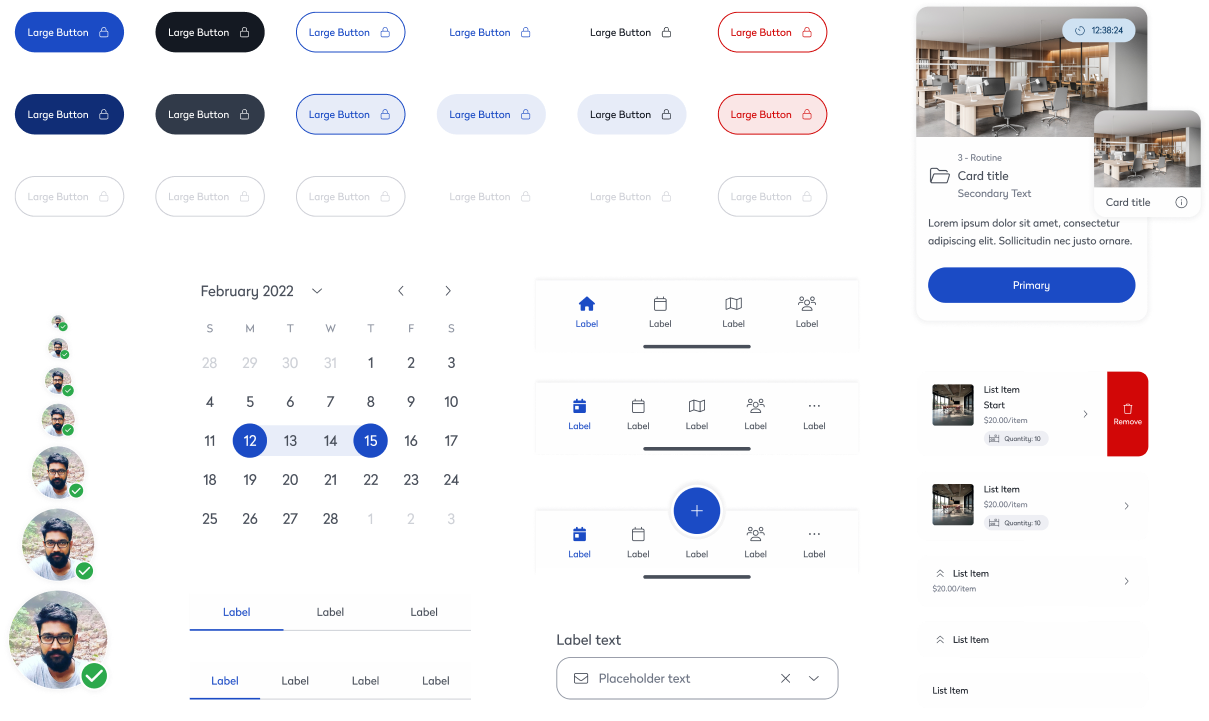

Integration of the Evo Design System

To ensure a seamless user experience, the Evo Design System was integrated into the Asset platform, unifying UI components across modules. Standardized elements improved usability, reduced inconsistencies, and brought clarity to the interface. The system also enhanced collaboration between design and engineering, accelerating development and improving overall efficiency. Built-in accessibility guidelines ensured the platform remained inclusive and user-friendly for all.

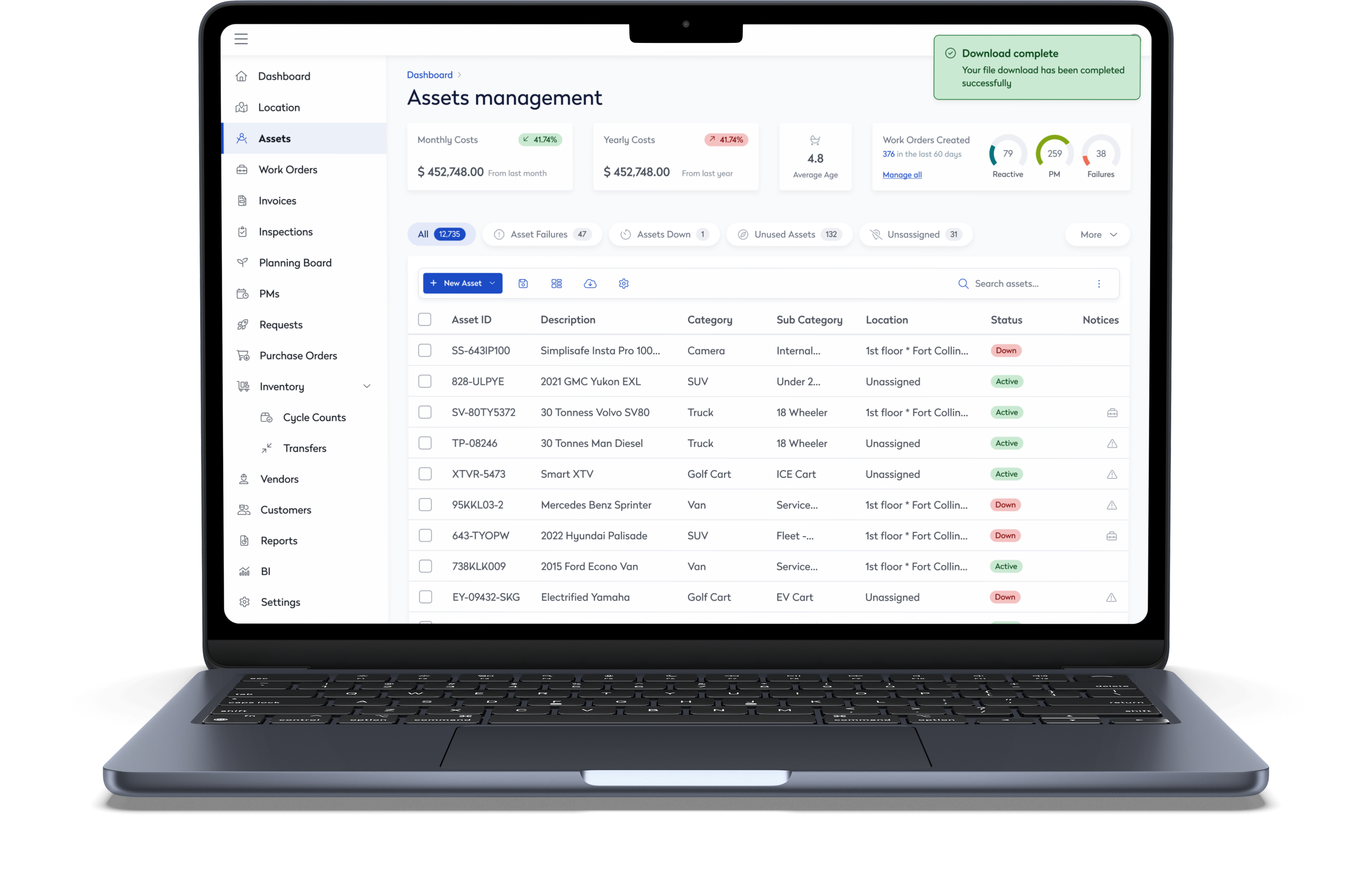

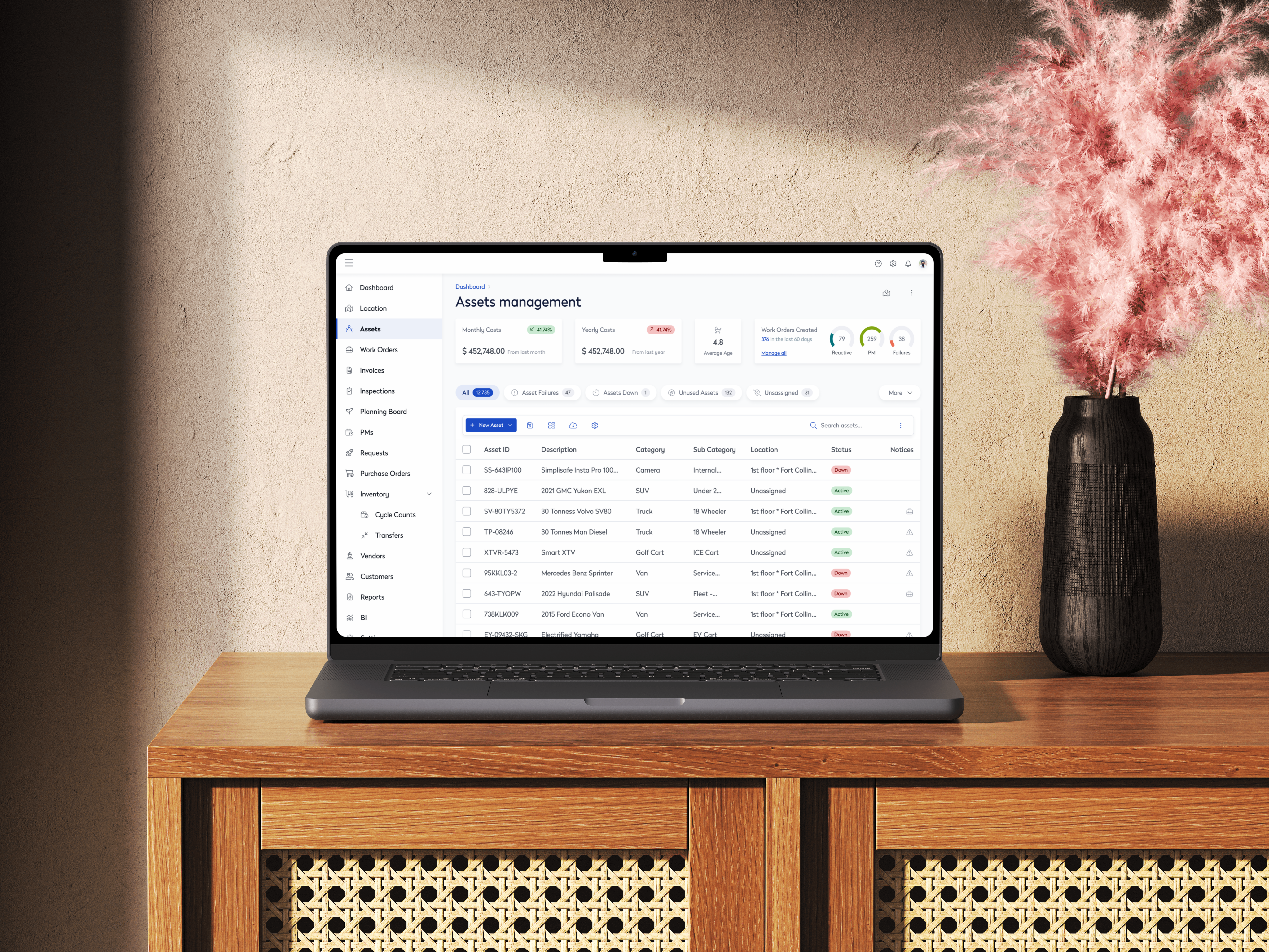

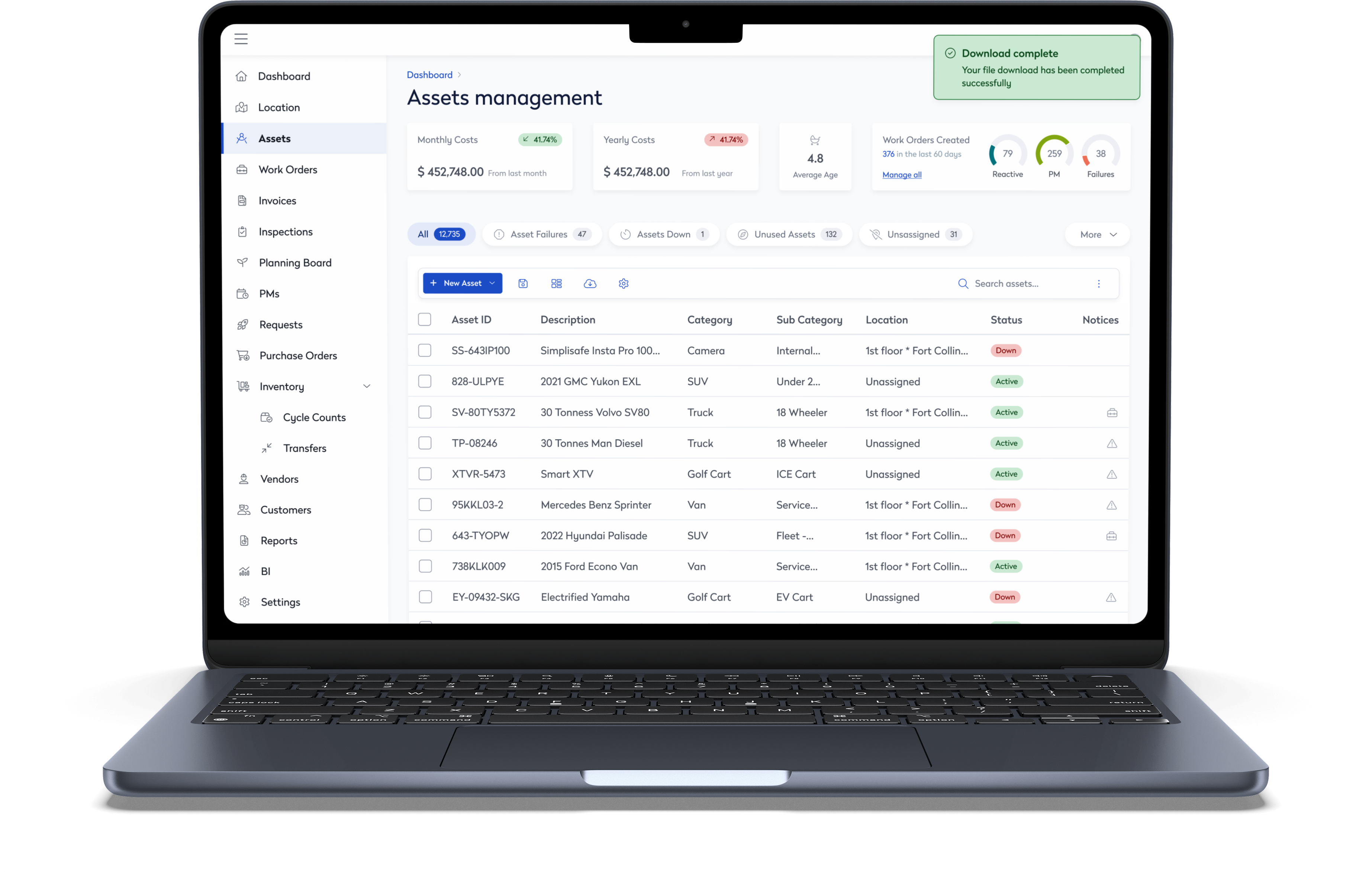

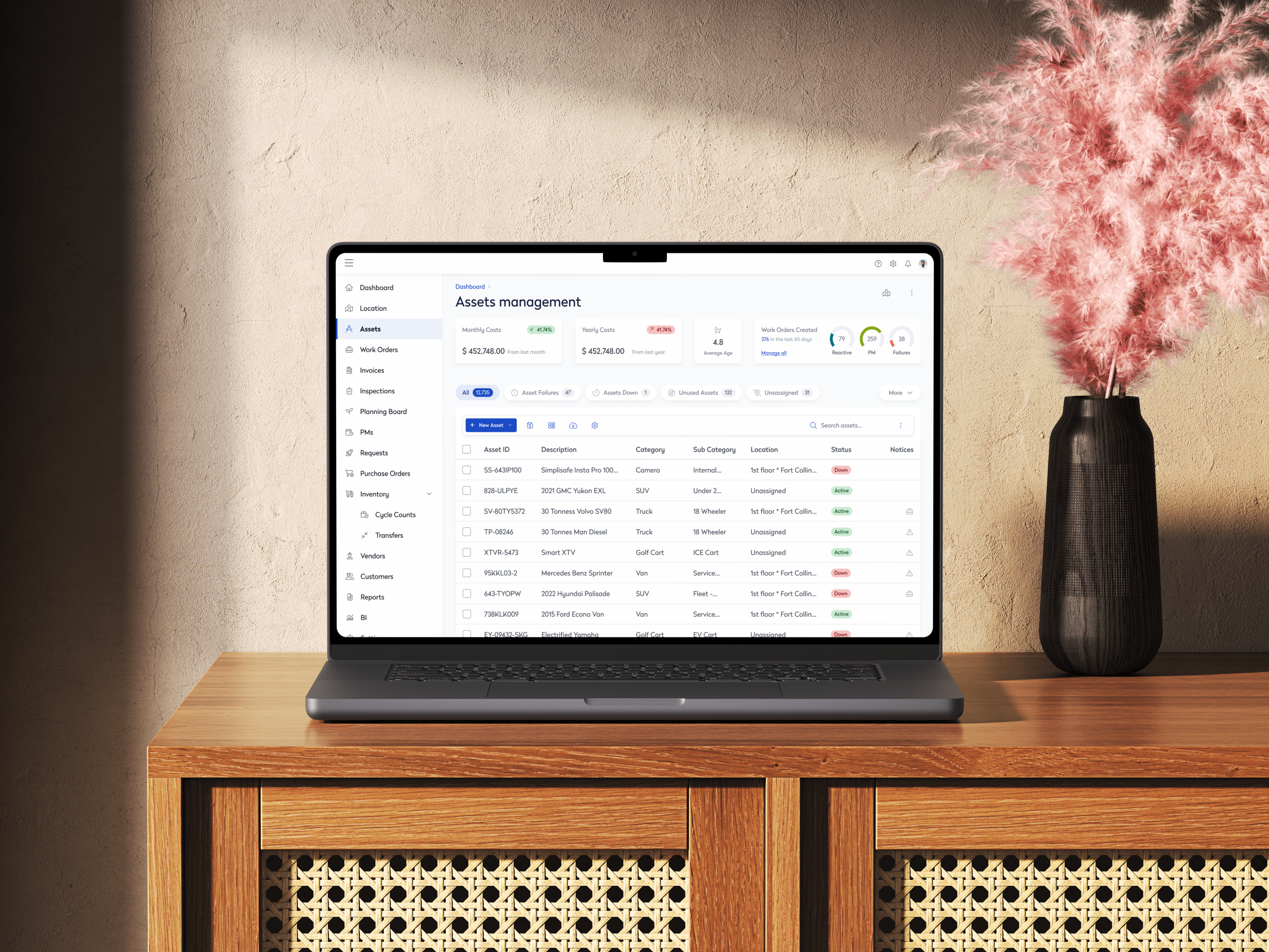

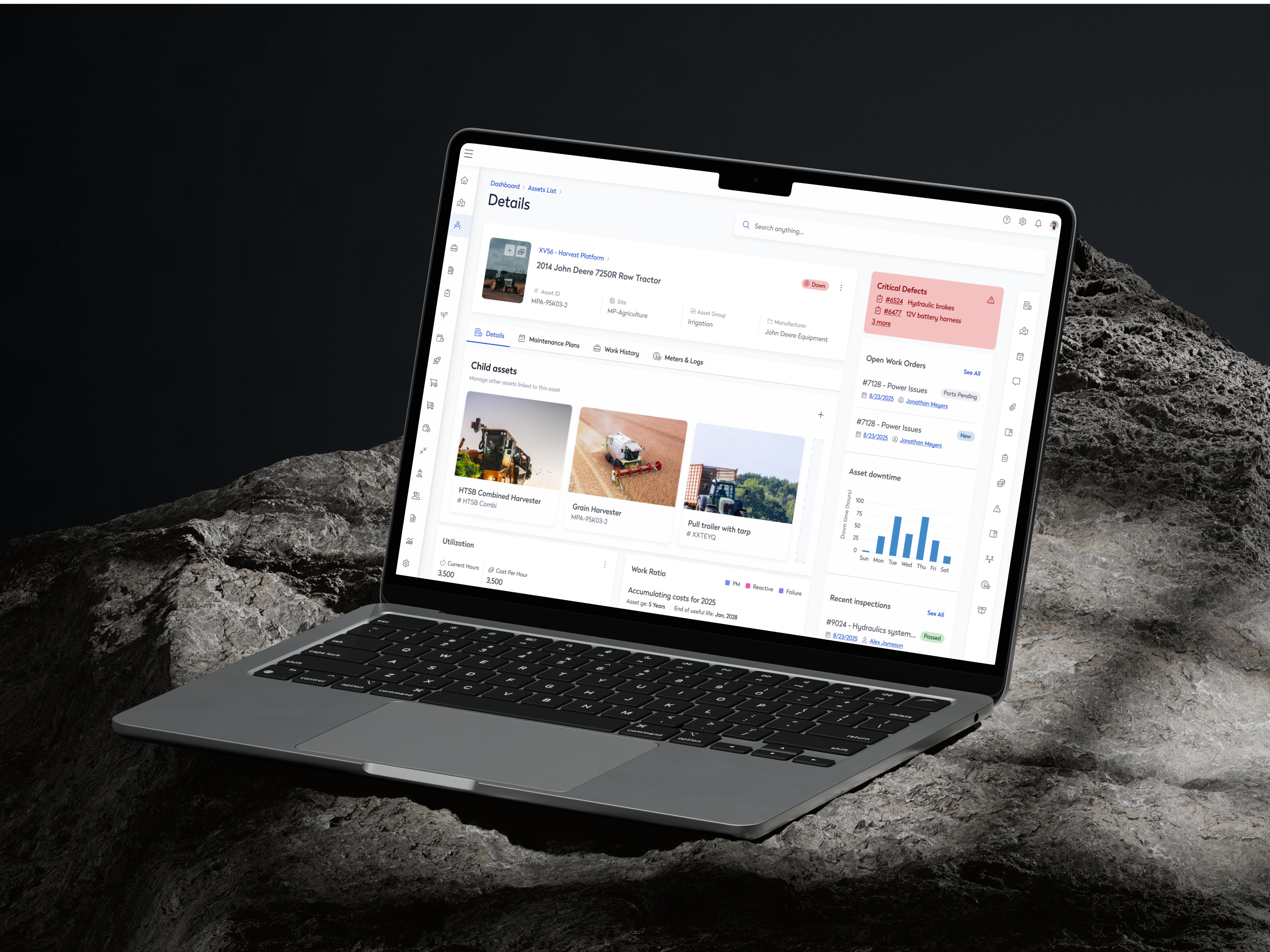

Development of a Global Dashboard

A centralized dashboard was built to give organizations a real-time view of all facilities and assets, enabling performance monitoring and operational optimization. It offers insights into asset utilization, maintenance needs, and trends for proactive management and cost savings. Advanced filters and search streamline navigation, while customizable views let users focus on key metrics, improving decision-making and efficiency.

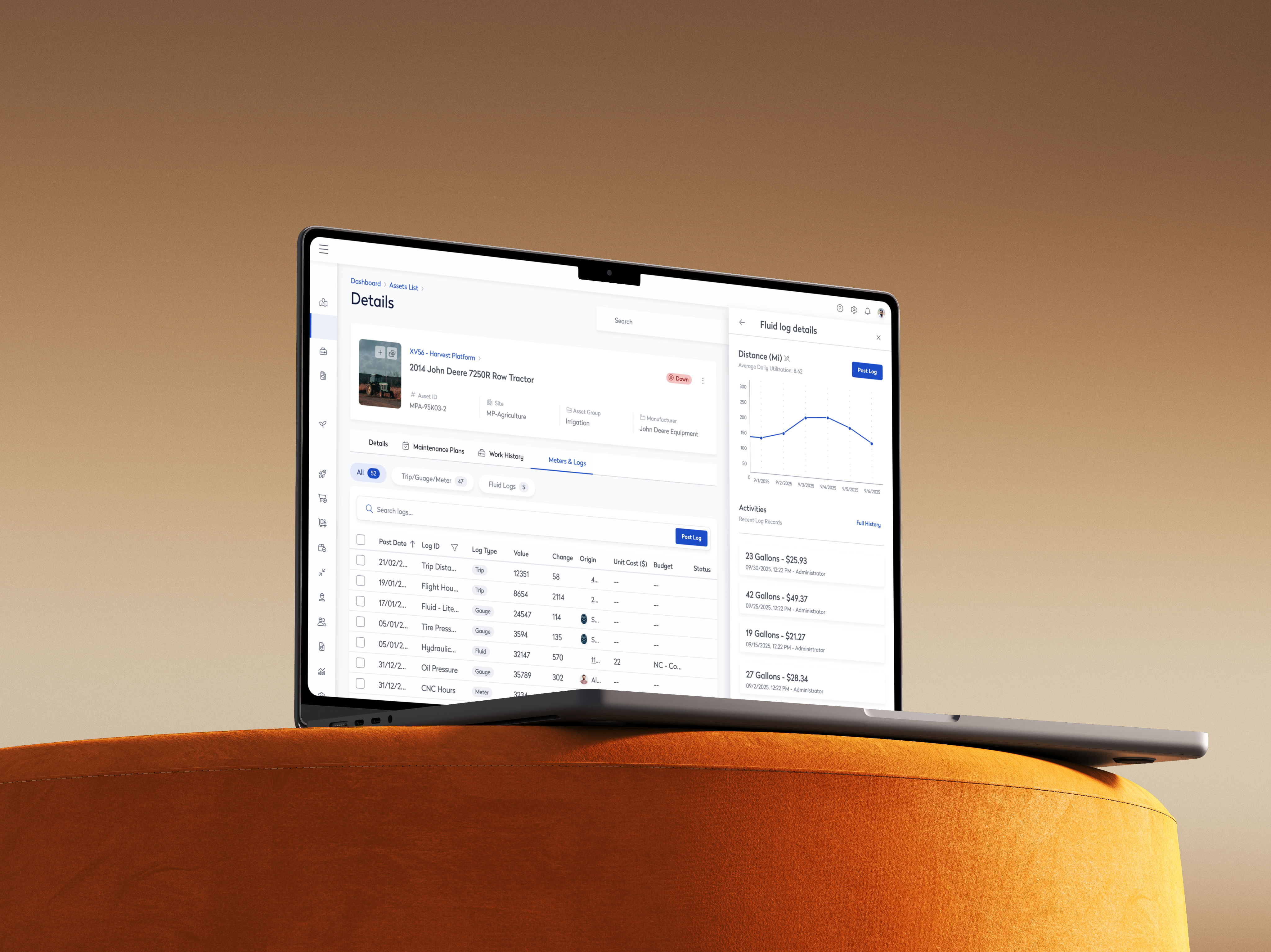

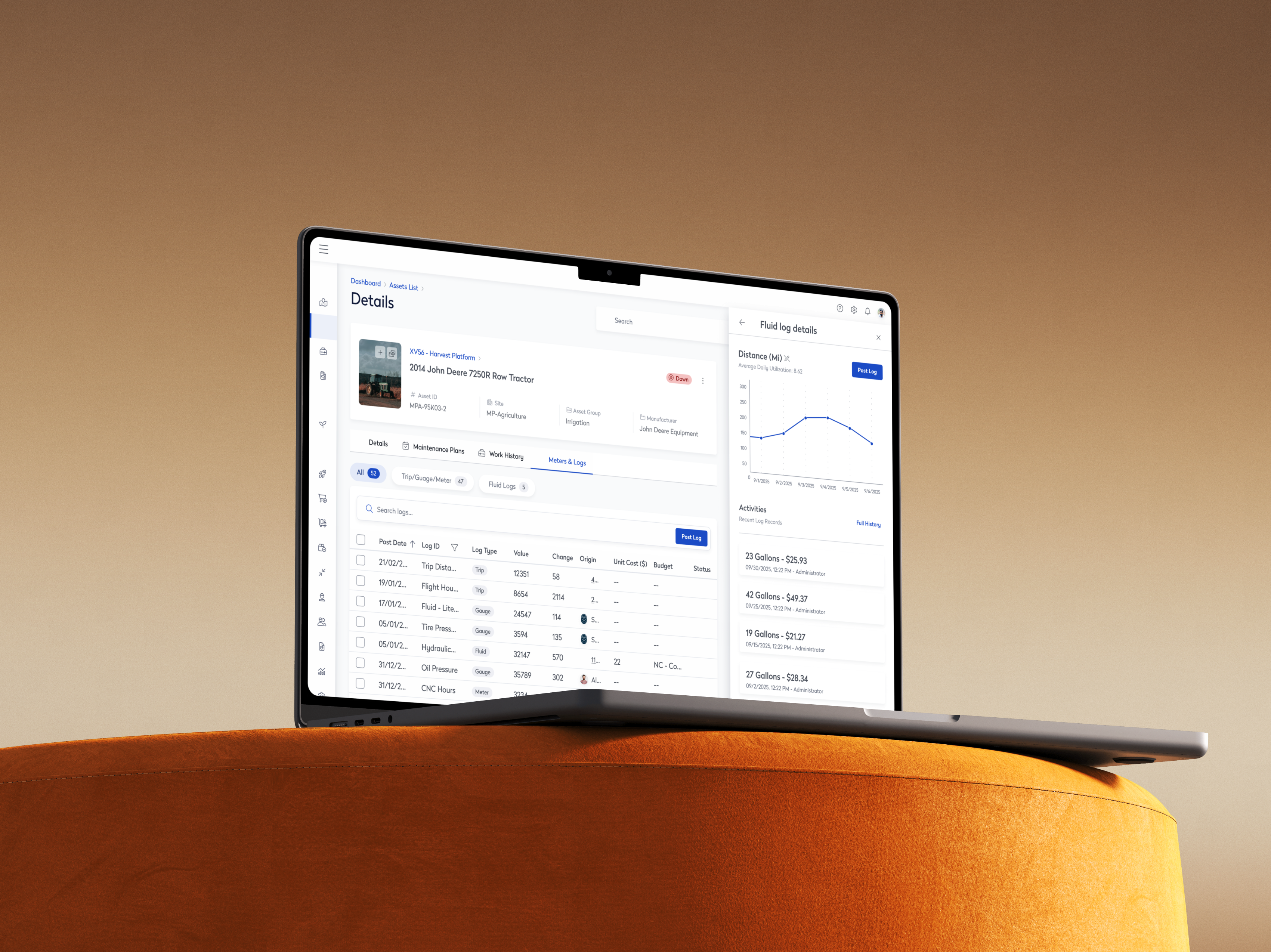

Expansion of Asset Intelligence

New features were added to improve asset and facility management through deeper insights and smarter decisions. Predictive Maintenance uses real-time and historical data to anticipate failures, cutting downtime and costs. IoT-enabled Asset Tracking enhances visibility of location and condition, while Advanced Reporting Tools help optimize utilization and streamline maintenance planning.

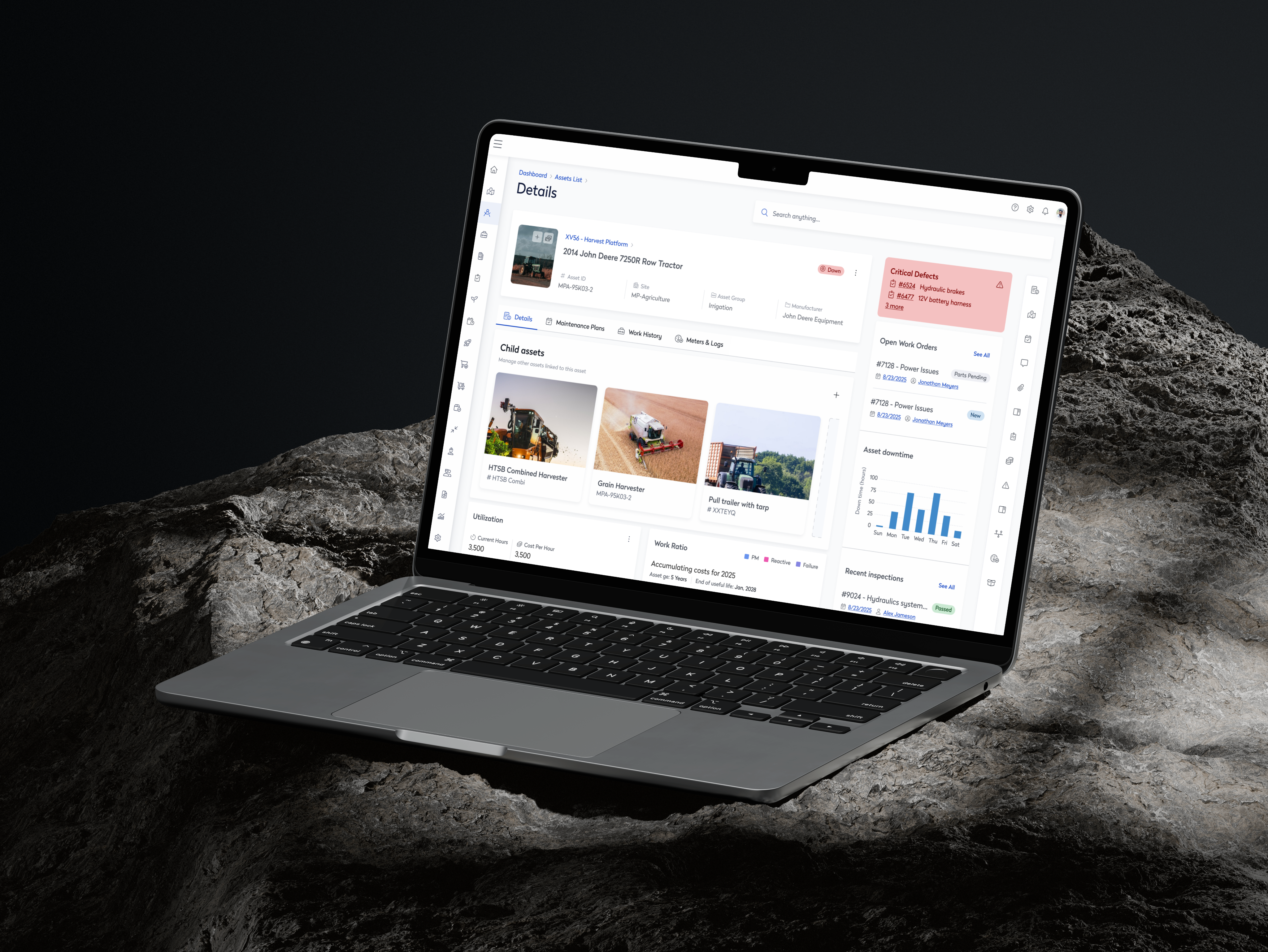

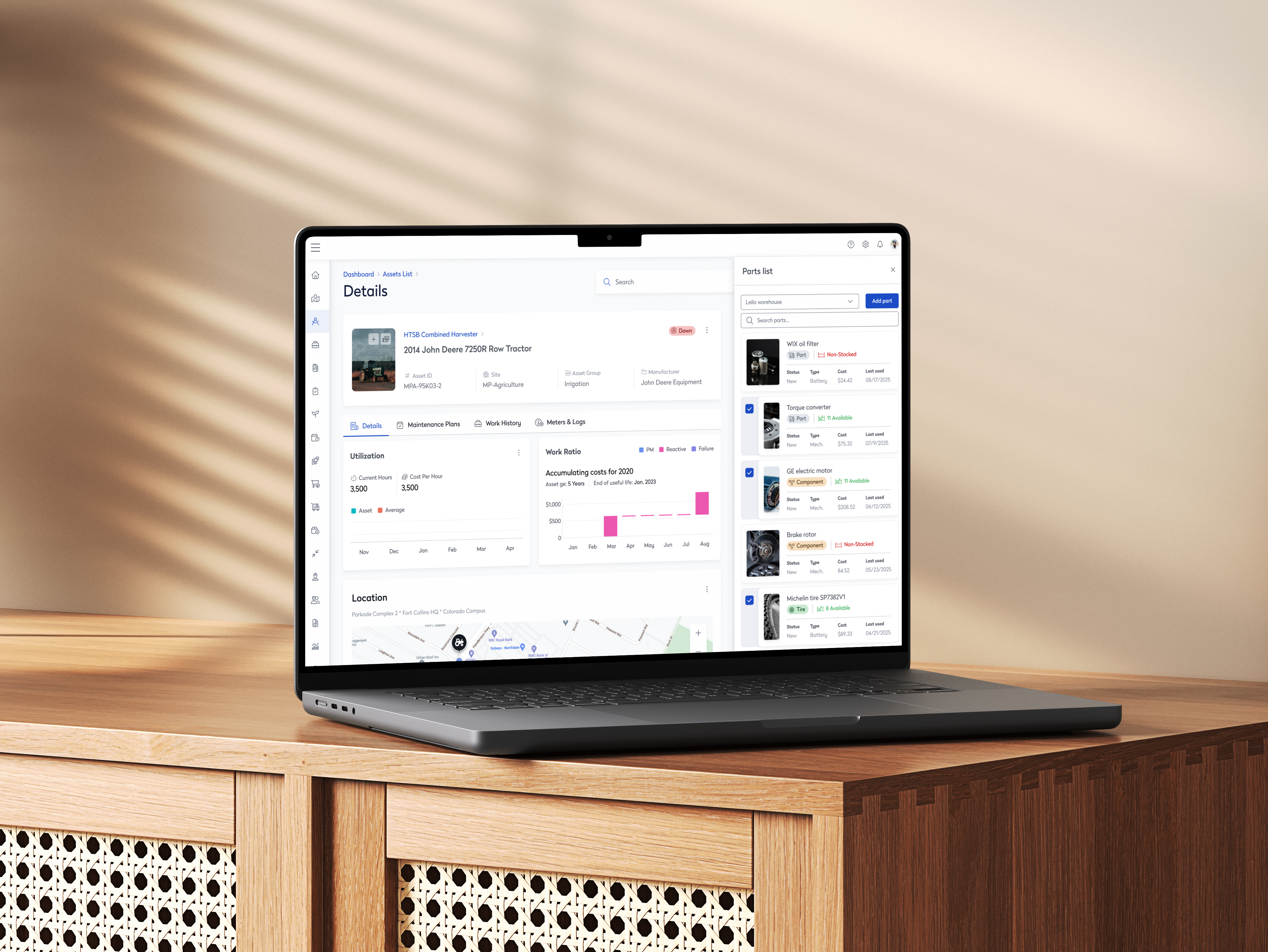

Unified Asset and Parts Management

To improve efficiency and reduce context switching, we integrated parts management directly into the asset detail view. Users can now monitor asset performance—such as utilization, cost per hour, and maintenance history—while managing associated parts from the same screen. The right-side panel provides real-time access to parts by location, with clear labels for availability, type, and cost. Technicians can quickly search, filter, and add parts without leaving the workflow. This streamlined approach improves decision-making, speeds up maintenance planning, and supports a more seamless user experience.

Research

Research That Uncovered System-Wide Gaps

Identifying Breakdown Points Across the Ecosystem

To guide improvements, we conducted an internal audit of asset workflows, analyzing how users navigated tasks across web and mobile. Product telemetry revealed drop-offs, slow completions, and repeated actions—signaling friction. Users struggled with inconsistent layouts and lacked visibility to manage high-volume assets effectively.

Insights from Operators and Facility Managers

We paired data with interviews across roles—technicians, admins, and compliance leads—to surface issues metrics missed. Common pain points included poor visibility across asset lifecycles, duplicate data entry, and low trust in reporting. These insights shaped our priorities: standardization, centralization, and real-time transparency.

40% Fewer Steps

Streamlined workflows eliminated redundant actions across modules.

No More Spreadsheets

Integrated dashboards replaced 3rd-party tracking tools.

1 Platform, Not 3

Merged asset, parts, and maintenance tools into one system.

Outcome

Unified Management

Users now have a centralized platform to monitor and manage assets across all facilities, leading to informed decision-making and optimized asset utilization.

Consistent & Intuitive UX

The standardized UI components and design principles from the Evo design system have resulted in a cohesive and user-friendly interface, enhancing user satisfaction.

Operational Efficiency

The new mobile and web applications have streamlined workflows for technicians and operators, reducing downtime and improving maintenance processes.

Enhancing Assets Management with Dashboard & Design System Integration

Background

The Asset platform helps organizations track assets, streamline operations, and ensure compliance. However, improvements were needed to enhance visibility, reduce friction, and drive greater operational efficiency.

Overview

Adding a global dashboard and integrating the Evo Design System improved user experience by enhancing visibility, simplifying workflows, and strengthening compliance. This case study covers the challenges, solutions, and impact.

Assets Management

Problem

Addressing Critical Issues in Asset Oversight

Fragmented Asset Visibility

Without a unified view, managing assets across multiple facilities was inefficient and fragmented, causing delays and making it harder to make informed, timely decisions.

Inconsistent User Experience

The lack of a standardized design system caused inconsistent UI components and a disjointed interface across modules.

Limited Functionality

Users needed advanced features like improved tracking, maintenance capabilities, and comprehensive reporting tools to support complex operations and ensure compliance.

Solution

Enhancing Visibility and Consistency

Integration of the Evo Design System

To ensure a seamless user experience, the Evo Design System was integrated into the Asset platform, unifying UI components across modules. Standardized elements improved usability, reduced inconsistencies, and brought clarity to the interface. The system also enhanced collaboration between design and engineering, accelerating development and improving overall efficiency. Built-in accessibility guidelines ensured the platform remained inclusive and user-friendly for all.

Development of a Global Dashboard

A centralized dashboard was built to give organizations a real-time view of all facilities and assets, enabling performance monitoring and operational optimization. It offers insights into asset utilization, maintenance needs, and trends for proactive management and cost savings. Advanced filters and search streamline navigation, while customizable views let users focus on key metrics, improving decision-making and efficiency.

Expansion of Asset Intelligence

New features were added to improve asset and facility management through deeper insights and smarter decisions. Predictive Maintenance uses real-time and historical data to anticipate failures, cutting downtime and costs. IoT-enabled Asset Tracking enhances visibility of location and condition, while Advanced Reporting Tools help optimize utilization and streamline maintenance planning.

Unified Asset and Parts Management

To improve efficiency and reduce context switching, we integrated parts management directly into the asset detail view. Users can now monitor asset performance—such as utilization, cost per hour, and maintenance history—while managing associated parts from the same screen. The right-side panel provides real-time access to parts by location, with clear labels for availability, type, and cost. Technicians can quickly search, filter, and add parts without leaving the workflow. This streamlined approach improves decision-making, speeds up maintenance planning, and supports a more seamless user experience.

Research

Research That Uncovered System-Wide Gaps

40% Fewer Steps

Streamlined workflows eliminated redundant actions across modules.

No More Spreadsheets

Integrated dashboards replaced 3rd-party tracking tools.

1 Platform, Not 3

Merged asset, parts, and maintenance tools into one system.

Identifying Breakdown Points Across the Ecosystem

To guide improvements, we conducted an internal audit of asset workflows, analyzing how users navigated tasks across web and mobile. Product telemetry revealed drop-offs, slow completions, and repeated actions—signaling friction. Users struggled with inconsistent layouts and lacked visibility to manage high-volume assets effectively.

Insights from Operators and Facility Managers

We paired data with interviews across roles—technicians, admins, and compliance leads—to surface issues metrics missed. Common pain points included poor visibility across asset lifecycles, duplicate data entry, and low trust in reporting. These insights shaped our priorities: standardization, centralization, and real-time transparency.

Outcome

Outcomes That Transformed Operations

Unified Management

Users now have a centralized platform to monitor and manage assets across all facilities, leading to informed decision-making and optimized asset utilization.

Consistent & Intuitive UX

The standardized UI components and design principles from the Evo design system have resulted in a cohesive and user-friendly interface, enhancing user satisfaction.

Operational Efficiency

The new mobile and web applications have streamlined workflows for technicians and operators, reducing downtime and improving maintenance processes.

Explore more work

Workplace Engage

Mobile app for hybrid teams. Simplified way finding, desk booking, and workplace scheduling.

Evo Design System

A scalable design system used across 4 platforms. Built for speed, clarity, and dev alignment.